Fox Inground Pools

Pool Structures

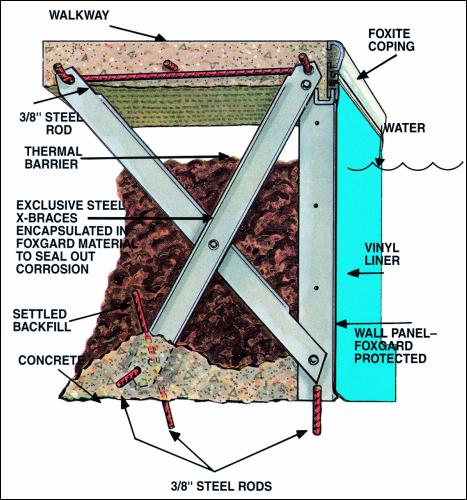

X-Brace® Technology Fox pools use some of the same technology used in building bridges, tall buildings, water towers, and other structures that require high strength due to high stresses. Your swimming pool holds thousands of gallons of water while holding back thousands of pounds of earth. In order to ensure structural integrity over many years it’s important that your pool walls will remain intact regardless of external forces. With the Fox X-Brace technology you get just that. Patented by Fox, the X-Brace structure provides 100% support for your pool walls without concern for internal or external pressures. |

X-Brace® Details -Pool panels are supported every 4 feet by the patented Fox X-Brace

The Benefits of the Fox X-Brace® -Self-supporting structure at all times |

FoxGard® a Proven Process We take an extra step when it comes to manufacturing our pools. Each piece of 14 gauge, pre-galvanized steel is totally encapsulated, front and back, with a special powder coating, fusion bonded to the steel at 400 degrees to lockout rust and corrosion. The FoxGard® process of powder coating is used in a variety of other applications where superior corrosion resistance is required. Everyday items like outdoor furniture, electrical and metering devices that endure constant weathering conditions, stadium seats, and other outdoor recreational devices employ powder coating protection. The FoxGard® fusion bonded protection -Complete rust resistant coverage over welds, corners, and edges

|

Freeform Panels Fox’s freeform panels allow you to design virtually any shape pool you want. Fox panels are made to flex laterally while remaining extremely strong vertically. |

The Construction Process

Step 1: Excavation

The pool is excavated according to the dig drawings at the location your Fox dealer indicated. A three foot section is excavated outside the wall area to facilitate the wall assembly, X-Braces™, plumbing, and concrete footer.

Step 2: Wall Assembly

The pool walls are assembled on the perimeter. The X-Braces™ are attached every four feet, plumbing roughed in, and the footer is poured. At this time Fox Stairs, Buddy Seats®, Swim-Outs, and all integral parts of your Fox pool wall system are added.

Step 3: Backfill

Once the walls are assembled and the footer is completed, the pool can be backfilled, if desired. Backfilling is not necessary at this time as the patented X-Braces™ are designed to support the pool walls independently, even when filled with water. In most cases, your Fox dealer will backfill your pool walls and pour the deck, prior to finishing the bottom and installing the liner.

Step 4: Concrete Decking

Once the backfill is complete, steel reinforcing rods are added throughout the perimeter of the pool, attached to the X-Braces™, to form the foundation for your pool deck. Concrete is poured into forms and finished to your specifications. With a Fox pool, you don't need to compact the earth underneath or wait for it to settle. The patented X-Braces™ completely support the concrete deck. When the backfill does settle, it actually forms a protective barrier below the concrete, preventing heaving in the winter when the ground freezes.

Step 5: Finishing the Bottom

Prior to installing the Fox liner, your Fox dealer will finish the pool bottom with a mixture of concrete and sand or vermiculite. This material is applied approximately 1.5 to 2 inches thick over the bottom and is troweled smooth by hand.

Step 6: Installing the Liner

As soon as the bottom is finished, the Fox liner is spread across the pool and dropped into place. The top edge of the liner hooks neatly into the Foxite II coping while the remainder is drawn tight around the pool sides and bottom with a special vacuum. Once a foot or so of water is in the pool, your Fox dealer attaches the fittings and cuts away the excess liner material from around the stairs.

Step 7: Enjoy your new pool!

When the pool is full, We will test all of the components, add sanitizers as necessary, and review their operation with you.